It is the process of removing contaminants from wastewater and household sewage, both affluent and domestic. Wastewater from flushing the toilet, bathing, cleaning sink, and general regular goes down the drain and into a pipe, which joins a large sewer pipe under the road. The larger pipe also joins a major pipe that leads to the treatment canter.

There is 2 Type of Sewage Treatment Method:- Aerobic and Anaerobic.

1.Aerobic:-Sewage treatment in the presence of Oxygen Like MBR, MBBR, SBR- where aerators/blowers are installed generally no smell during treatment.

2.Anaerobic:-Sewage treatments in the,[op[ absence of Oxygen-UASB-No aerators / blowers are required-foul smell during treatment.

Aerobic Treatment:-Continuous pumping of Oxygen is required to maintain treatment process. The aerators/blowers have to be operated continuously.

Aerobic Treatment Based Sewage Treatment Technologies:-

A.Moving Bed Bio film Reactor (MBBR)

B.Sequential Batch Reactor (SBR)

C.Up flow Anaerobic Sludge Blanket Reactor (UASB)

What Is MBR…?

MBR water treatment plant uses the membrane bioreactor for Wastewater Treatment Plant Design that is the combination of the biological waste-water process and membrane process. This membrane bioreactor design is the most used process to treat sewage water.

What Is SBR…?

SBR- sequencing batch reactor plant uses the activated sludge to treat the wastewater. It is used for reducing the organic matters. It separates the water and activated sludge through the oxygen bubbles.

What Is MBBR…?

MBBR- moving bed bio film reactor sewage treatment plant is used in very less space, and that is known as a bio film process.

These are the common definitions of all the sewage treatment plants that ”Treated Water is Provided As Per PCB Norms”.

As per Current Scenario We will go for MBBR Technology for S.T.P:-

Advantages of MBBR

1: For Space Constraints, the Perfect Wastewater Solution

One of the most significant advantages of MBBR is that it does not necessitate a large amount of physical space. In fact, when compared to other biological water treatment systems, MBBR is noted for its minimal footprint. MBBR tank can treat the same volume of wastewater as a trickling filter or activated sludge tank while being a quarter of the size.

2: For inexperienced plant operators, it's simple to use

One of the other benefits of bio film reactors is that they are simple to use. The science behind this procedure is complicated, but the procedure itself is simple. Another advantage of MBBRs that make them a preferred alternative for many industrial facilities is that they are low-maintenance. Monitoring and running pumps and blowers, as well as performing routine maintenance on screening, clarifier, influent equalization, integrated control, and sludge handling systems, are all part of typical MBBR system maintenance.

3: Susceptible to Shock Loads

Another benefit of MBBR systems is that they are adaptable and can handle variable loads. This means they can successfully withstand shock loads.

4: With a short hydraulic retention time, it works quickly

Hydraulic retention time (HRT) is a metric that indicates how long it takes a water treatment system to adequately treat the influent. This can take a long time on some systems, implying that the procedure is slow. Less wastewater can be treated in a given length of time if the procedure is slower.

MBBR Highlights: -

Using moving bed bio film reactors over other, traditional wastewater treatment processes can be a strategic move for many industries, since MBBR comes with a host of exceptional qualities.

Compact: - MBBR is an excellent option for facilities with space constraints, since it typically has a much smaller footprint than other systems. An MBBR aeration tank can effectively treat the same amount of water as a much larger tank used for a more traditional process. Primarily, it offers this benefit due to the maximized surface area the media provide for bio film growth.

Simple: - Another practical advantage of MBBR is that it is a relatively straightforward process. MBBR allows nature to take its course, which minimizes the role of the operator. It is worth noting that operators must be knowledgeable about the process so they can ensure everything is working properly at the molecular level. However, the process itself does not require very many steps.

Low maintenance:- MBBR is also known for being a low-maintenance process. Maintenance tasks like backwashing that an operator would have to perform in other cases are typically unnecessary with MBBR. This system is largely self-moderating, so users can trust it to operate effectively without the need for demanding, ongoing maintenance.

Flexible: - MBBR is naturally able to adjust as needed to varying loads and changes in the influent, since the microorganisms on the carriers respond to changes. It allows MBBR systems to resist shock loading or a sudden spike in pH levels. A 2014 study of MBBR demonstrated the system’s ability to remain highly stable when faced with organic, hydraulic and salt shock loadings and to quickly return to normal.

Efficient: - One of the most significant advantages of MBBR is its impressive level of efficiency. An MBBR system can work much more quickly than alternative methods to treat the water. The hydraulic retention time (HRT) for BOD and nitrogen removal with an MBBR is around three to four hours. The continuously moving media and the sheer amount of bio film make this low HRT possible.

Note: - MBBR Technology is Able to Handel all Type of Grey and Black Water at High and Low MLSS, with Quickly BOD and COD Removal

Moving bed bio film reactor (MBBR) is a biological technology used for wastewater treatment process suitable for municipal and industrial application. Another common name is moving bed film reactor. It was invented in the 1980s. MBBR offer an economical solution for wastewater treatment. STP MBBR technology is the use of a moving bed bio film reactor in sewage treatment plants.

MBBR wastewater treatment system enables efficient results of the disposal using low energy. The technology is used to separate organic substances, nitrification and de nitrification. MBBR design is made of an activated sludge aeration system. The sludge is collected on the plastic carriers which have a large internal surface area. The surface area in the carriers optimizes the contact of water, air, and the bacteria. MBBR activated sludge is the application of MBBR media to an overloaded treatment plant when upgrading.

MBBR is applicable to the different quality of wastewater treatment. The application is determined by the desired results and regulations controlling discharge. The system can be of more than one stage depending on specific needs. The stages are made of individual tanks separated by screens to ensure that bacteria remain in their specific tank.

MBBR Media Used in Wastewater Treatment

Aeration tank: The tank is similar to an activated sludge tank. The aeration is used to keep in motion the activated sludge and carriers. The MBBR system separates the excess bacteria and sludge which are directed to the final separator.

Special plastic carriers: They provide a surface for bio film growth. Carrier materials are made of materials with a density close to that of water (1g/cm3) an example is high-density polyethylene (HDPE) with a density of 0.9g/cm3. These carriers are moved in the tank through the aeration system. This ensures good contact between thewastewater and the biomass on the carriers.

Conclusion:-

The quantity of biomass plays a big role in the removal efficiency of the MBBR system; it can be increased through the volume of carriers per unit. The carrier’s performance needs to be proven for specific wastewater treatment for application of different cases. Design of a water treatment plant should not be based on assumption or estimation but the correct material should be used for the carrier and the volume required calibrated.

MBBR technology is effective for wastewater treatment if the regulation concerning the effluent water discharge. The system is flexible in its application and can easily be relocated. Wastewater treatment as required for ecological reasons can be done using the MBBR.

MBBR BASED SEWAGE TREATMENT PLANT EQUIPMENTS:-

1.Bar Screen

2.Equalozation Tank

3.Areation Tank / MBBR Tank

4.MBBR Media / Bio Cell

5.Tube Settler

6.Sand & Carbon Filter

7.Pipe Floculator

8.Screw Press For Sludge Dewatring

9.Ultraviolent Light

Note :- All ABOVE MBBR Technologies Based Sewage Treatment plant Equipment are Only a Example.

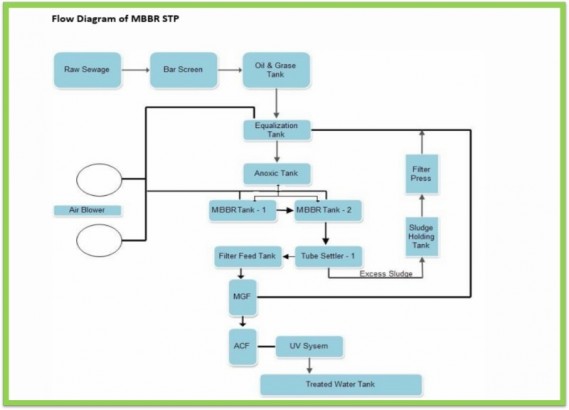

Flow Diagram MBBR STP:-

Dear member we are very honorable personility, If you want to communication with us,Then leave your message here

Call Now: +91-9828121516,8949293547

Email: willmerecotechnologies@gmail.com